CATALYTIC CONVERTERS

MANIFOLD MOUNTED CATALYTIC CONVERTERS | CLOSE-COUPLED CATALYTIC CONVERTERS

TURBO-BACK CATALYTIC CONVERTERS | UNDERBODY CATALYTIC CONVERTERS

100%

EXCEPTIONAL QUALITY

Catalyst by UMICORE AUTOCAT, IATF 16949 quality systems and highest grade materials to give you best in market catalytic converters

PRECISE FITMENT

With nearly 30 years experience in supplying catalytic converters we know the importance of getting the part to fit right and fit quick

COST ADVANTAGES

Durability, ease of fitment, premium quality materials and the use of efficient manufacturing methods gives Cateran a cost advantage over its competitors

DO IT FAST. DO IT ONCE. DO IT RIGHT.

Cateran offers a rapidly growing range of premium quality direct fit replacement catalytic converters to the North American aftermarket. Focusing on difficult to reproduce parts, Cateran Inc. utilizes the latest design and manufacturing technology and the highest grade materials available including catalyst by UMICORE AUTOCAT, the world’s leading OEM catalyst supplier, to provide best-in-market product. This makes Cateran the Installer’s First Choice.

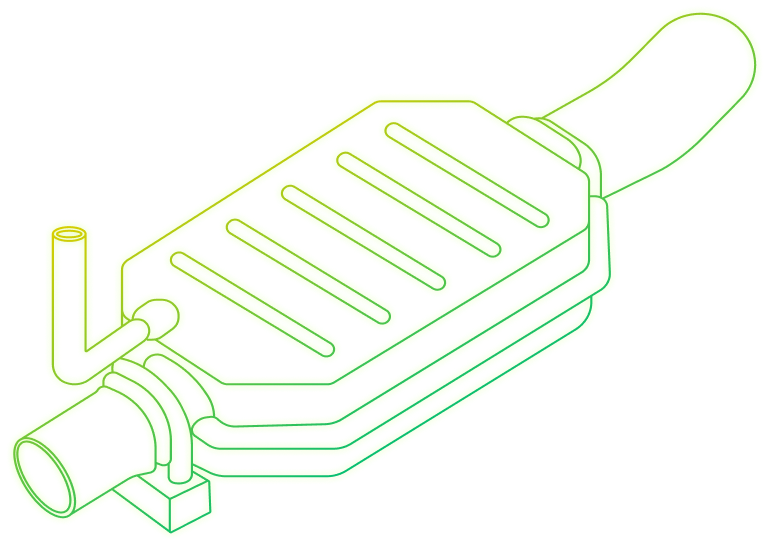

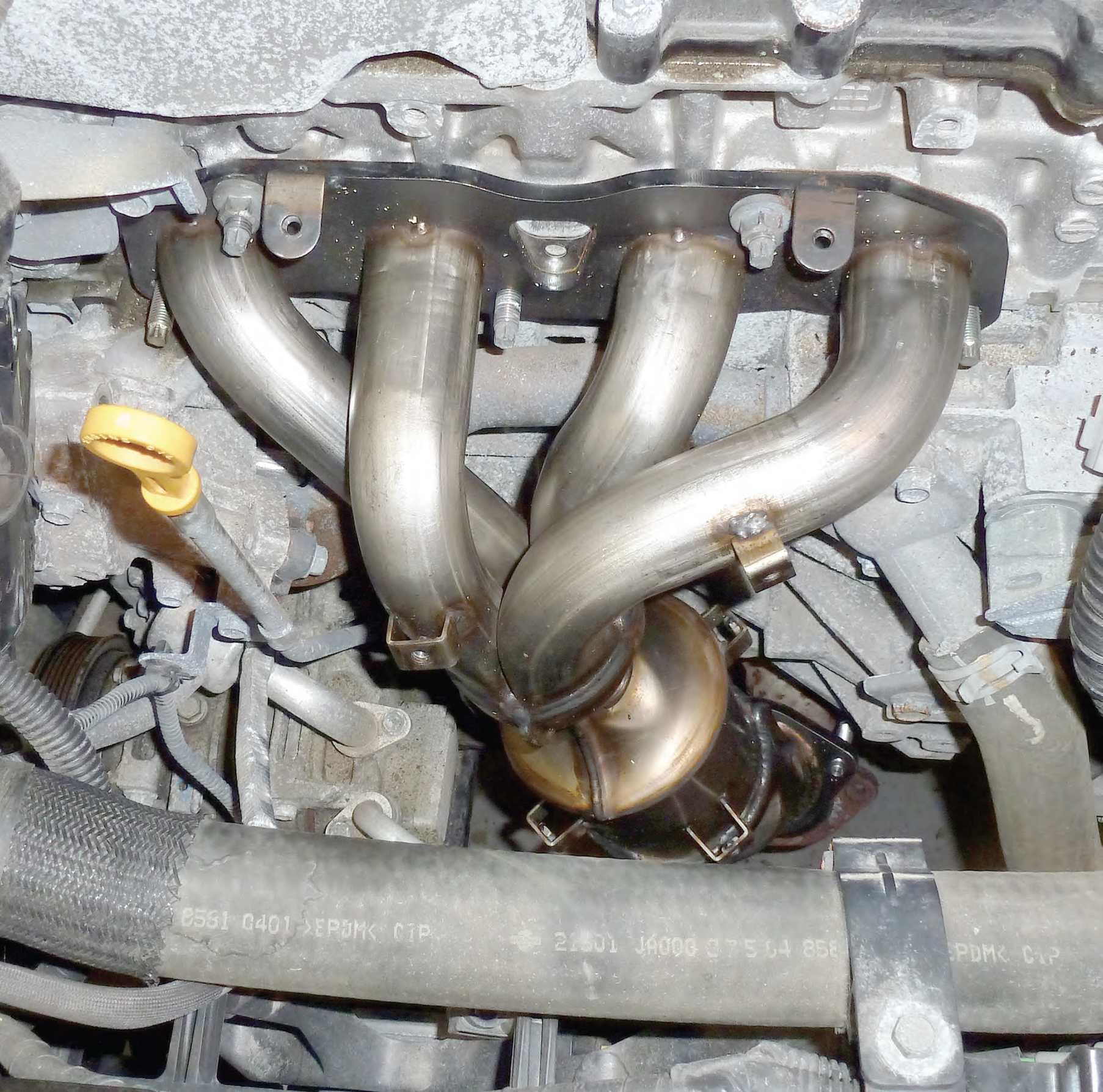

MANIFOLD MOUNTED CATALYTIC CONVERTERS

A manifold-mounted catalytic converter is a catalytic converter that is integrated directly into the exhaust manifold of a motor vehicle’s internal combustion engine. Manifold-mounted catalytic converters offer advantages over underbody catalytic converters in terms of quicker response to exhaust gas temperature changes, improved emissions control, and space efficiency. Being closer to the engine, they reach optimal operating temperatures faster, enhancing their effectiveness in reducing emissions.

This design is used to improve cold start emissions and overall catalytic converter performance in modern vehicles. This is achieved by burning off the excess hydrocarbons, which result from the extra-rich air-fuel mixture required for a cold start. Additionally, the integration with the exhaust manifold allows for a more compact design, which can be beneficial for space-constrained engine compartments.

CLOSE-COUPLED CATALYTIC CONVERTERS

A close-coupled catalytic converter is a catalytic converter that is bolted directly to the exhaust manifold on non-turbocharged vehicles. This design, like the manifold-mounted catalytic converter, minimizes the distance between the engine’s exhaust ports and the catalytic converter, which helps the converter reach optimal operating temperatures quickly, enhancing its efficiency in reducing emissions.

This design is commonly used to improve cold start emissions and overall catalytic converter performance in modern vehicles. This is achieved by burning off the excess hydrocarbons which result from the extra-rich mixture required for a cold start.

TURBO-BACK CATALYTIC CONVERTERS

A turbo-back catalytic converter is a catalytic converter that bolts directly to the to the exhaust outlet of the turbocharger on turbocharged motor vehicles. This design, like the manifold-mounted catalytic converter, minimizes the distance between the engine’s exhaust ports and the catalytic converter, which helps the converter reach optimal operating temperatures quickly, enhancing its efficiency in reducing emissions. As engines become smaller to meet more stringent emission requirements the use of turbochargers has become more common to increase power. The higher temperatures generated by the turbocharger can lead to premature degradation of the catalytic converter, reducing its efficiency and lifespan. Additionally, oil leaks in the turbocharger can poison the turbo-back catalytic converter. Properly maintaining the motor vehicle will increase the lifespan of the turbo-back catalytic converter.

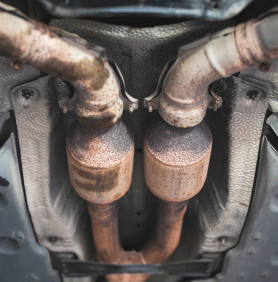

Y-PIPE CATALYTIC CONVERTERS

A Y-pipe catalytic converter is a catalytic converter assembly commonly used in vehicles with V-shaped engine configurations, such as V6 or V8 engines. The catalytic converter assembly bolts directly to the exhaust manifolds of both banks of engine. The “Y-pipe” refers to the shape of the pipe, which combines the two exhaust paths from each side of the engine into a single path, forming a “Y” shape. The assembly has monitored catalytic converters close to each of the inlet ends, and in some circumstances, have an unmonitored catalytic converter positioned after the merge point of the Y-pipe.

The Y-pipe design helps streamline exhaust flow, improving engine efficiency and overall vehicle performance while maintaining compliance with emission standards. Fitting an aftermarket Y-pipe catalytic converter assembly with the “Y” merge in the wrong place or with substandard internal materials can negatively affect the performance of the engine.

OEM Y-pipe catalytic converter systems are usually a complete welded assembly. Cateran splits the system to reduce packaging space and shipping costs. A clamp to join the left and right sections is provided with the assembly.

UNDERBODY CATALYTIC CONVERTERS

An underbody catalytic converter is a catalytic converter positioned beneath the vehicle, typically along the exhaust system. It is located further downstream from the engine than a manifold-mounted catalytic converter or close coupled catalytic converter. Underbody catalytic converters are typically fitted to older motor vehicles or larger engine motor vehicles.

The emission requirements for modern vehicles often mean that the motor vehicle may have a combination of manifold-mounted or close coupled catalytic converters and underbody catalytic converters. It is advisable to check the operation of the underbody catalytic converters if the close coupled or manifold-mounted catalytic converter require replacement.

WHAT IS CATALYTIC CONVERTER?

A catalytic converter is an emissions control device that converts toxic gases and pollutants in exhaust gas to less toxic pollutants by catalyzing a redox reaction (an oxidation and a reduction reaction). Catalytic converters are used with internal combustion engines fueled by either petrol (gasoline) or diesel—including lean-burn engines as well as kerosene heaters and stoves.